QWD Series Mesh Belt Type Shot Blasting Machine

1.Comprehensive tsananguro:

QWD yakatevedzana Mesh Belt Shot Blasting Machine imhando nyowani yemidziyo yakazvimiririra kugadzirwa nekambani yedu.

Panyaya yekutsanangudza michina yekuchenesa, inofanirwa kunge iri yeQ69 Series Kuburikidza nemhando Shot Blasting Machine.

Inonyanya kushandiswa kune pamusoro pepfuti inoputika muchina wematete-walled castings;simbi kana aluminium alloy castings iyo ine chimiro chemutete-madziro uye isina kusimba;Ceramics nezvimwe zvikamu zviduku, uyewo pakusimbisa basa-zvidimbu.

Iine maitiro ekuenderera mberi kwakanaka, kuchenesa kwepamusoro kushanda zvakanaka, diki deformation, hapana chikonzero chenheyo yemuchina, nezvimwewo inogona kushandiswa yoga kana pamwe chete nemutsara wekugadzira.

1.Comprehensive tsananguro:

QWD yakatevedzana Mesh Belt Shot Blasting Machine imhando nyowani yemidziyo yakazvimiririra kugadzirwa nekambani yedu.

Panyaya yekutsanangudza michina yekuchenesa, inofanirwa kunge iri yeQ69 Series Kuburikidza nemhando Shot Blasting Machine.

Inonyanya kushandiswa kune pamusoro pepfuti inoputika muchina wematete-walled castings;simbi kana aluminium alloy castings iyo ine chimiro chemutete-madziro uye isina kusimba;Ceramics nezvimwe zvikamu zviduku, uyewo pakusimbisa basa-zvidimbu.

Iine maitiro ekuenderera mberi kwakanaka, kuchenesa kwepamusoro kushanda zvakanaka, diki deformation, hapana chikonzero chenheyo yemuchina, nezvimwewo inogona kushandiswa yoga kana pamwe chete nemutsara wekugadzira.

2.Main technical parameters (QWD800):

| Aihwa. | Item | Zita | Parameter | Unit |

| 1 | Imba yekuchenesa | Saizi yekuvhura | W900*H480 | mm |

| 2 | Mesh bhandi | Mesh bhandi upamhi | 800 | mm |

| 3 | Kubudirira kwekugadzira | Frequency control | 0.5-1.8 | m/min |

| 4 | Impeller Head | Model | QBH037 | |

| Quantity | 8 | sets | ||

| Impeller diametr | 360 | mm | ||

| Abrasive flow rate | 8*180 | kg/min | ||

| Kuputika nekukurumidza | 76 | m/s | ||

| Simba | 8*11 | KW | ||

| 5 | Steel shot | Kutanga kuwedzera | 3 | T |

| 6 | Bucket lift | Kusimudza simba | 90 | T/H |

| Simba | 7.5 | KW | ||

| 7 | Horizontal Screw conveyor | Kutakura kugona | 90 | T/H |

| Simba | 7.5 | KW | ||

| 8 | Vertical Screw conveyor | Coveying capacity | 90 | T/H |

| Simba | 7.5 | KW | ||

| 9 | Separator | Fractional dose | 90 | T/H |

| Separation zone mhepo kumhanya | 4-5 | m/s | ||

| Kurasa zvinhu mushure mekuparadzana | ≦0.05% | |||

| Simba | 4 | KW | ||

| 10 | Mesh bhandi drive system | Simba | 3 | KW |

| 11 | Equipment ruzha | ≤93 | db | |

| 12 | Total power | 114 | KW |

3.Chigadzirwa Chimiro:

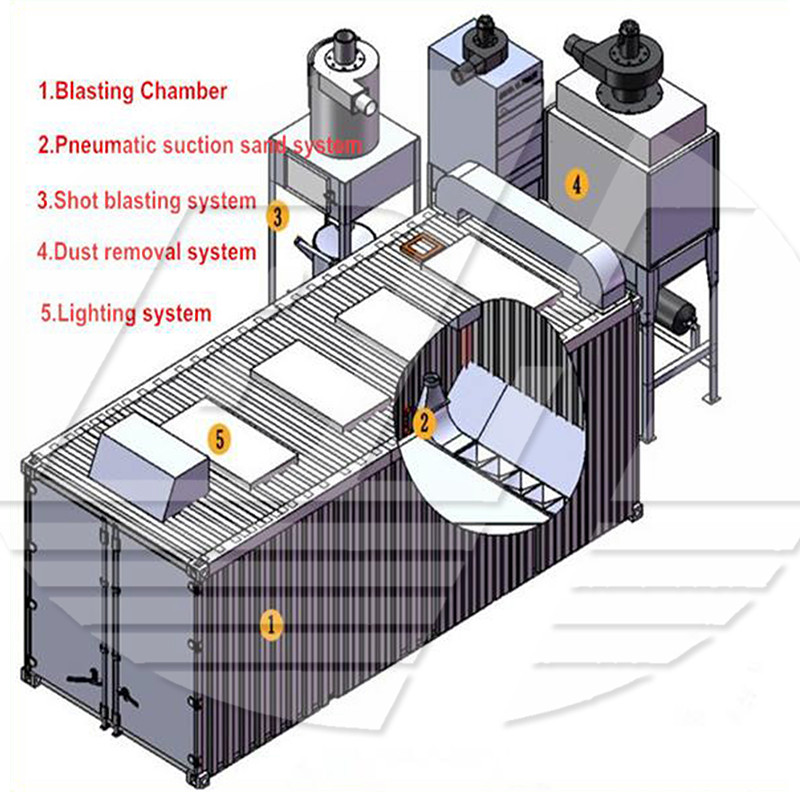

QWD Series Mesh Belt mhando Shot Blasting Machine inoumbwa neKuchenesa kamuri;Imba yekuisa chisimbiso;Mesh belt transmission system;Longitudinal Screw Conveyor;Horizontal Screw Conveyor;Bucket Elevator;Separator;Platform;Impeller Head Assembly;Simbi yekupfura kudzora system;Electric control system;nezvimwewo,

4.Main Features:

A.Shot Blasting yekuchenesa imba:

Imba yekupfura inoputika yekuchenesa imba inoumbwa nemadziro emadziro, magonhi ekupinda, madziro epamusoro, Mn13 yekudzivirira ndiro.

Goko rekamuri yekupfutirwa isimbi ndiro yakasungwa chimiro, inova yakavharwa uye yakapamhama nzvimbo yekushanda yekupfutirwa.

8 seti dzeQBH037 mhando Impeller Head assembly akaiswa pamadziro ekunze ekamuri yekupfutirwa.

Iyo Yakakomberedzwa Mn13 ndiro yekudzivirira mukamuri yekuchenesa yakatsikiswa zvine hexagon nzungu kuitira nyore disassembly uye kutsiva.

Yakakungurutswa Mn13 ndiro yekudzivirira ine kusimba kwakanaka uye pachena basa rekuomesa hunhu.(Pasi pechiito chesimba rakasimba remutoro kana mutoro wekuwedzera, iyo yakamanikidzwa nzvimbo inoomeswa, uye kuomarara kwepamusoro kunogona kuvandudzwa zvakanyanya kubva padanho rekutanga reHB170 kusvika pamusoro peHB550 nhanho, nepo musimboti uchiri kuchengetedza kunaka kwekusimba).

Iyo yekushanda-chidimbu inotakurwa kuburikidza nepfuti inoputika imba ne mesh bhandi.

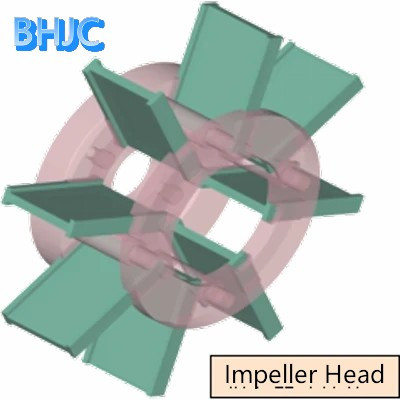

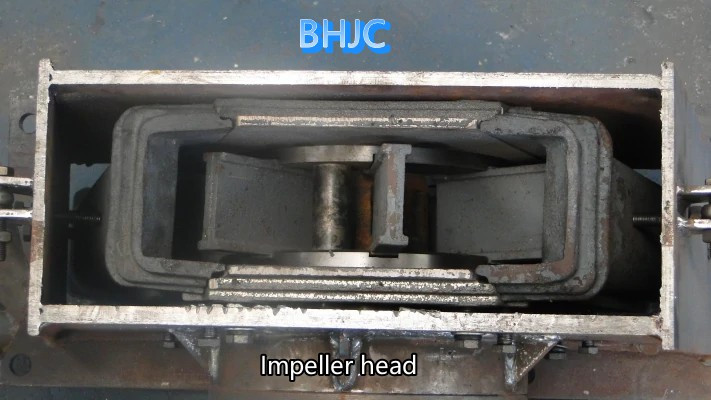

B.Impeller Head Assembly:

Iyo shot blaster assembly inoumbwa nepfuti blaster, mota, pulley, bhandi, bhandi chivharo, nezvimwe. Iyo dhizaini inotora B series V-belt.

Iyi mhando Impeller Head (QBH037) inobva paShinto yakanyura zvizere.Japan tekinoroji, uye mushure mekugara yakagadziridzwa, yakazvimiririra yakagadzirwa uye inogadzirwa isu pachedu.

Iine zvinotevera zvakanakira:

(1) Kushanda kwepamusoro: nechimiro chakakosha chevhiri rekupfura, kuputika kwepfuti kunogona kusvika 17.7kg/min · kW.

(2)Kurumidza kuisirwa uye kupatsanurwa kwemablades.

(3) Maburi eiyo shaft yakagadziriswa uye sleeve inotungamira pachivharo inogadziriswa panguva imwe chete:

a.Izvi zvinogona kuita mukaha pakati pedirectional sleeve uye pfuti inoparadzanisa vhiri yunifomu uye inowirirana.

b.Hazvingodzikisi kupfekwa kwevhiri rinopatsanura vhiri uye chiitiko chekutungamira sleeve kudzvanya, asi zvakare inonatsiridza zvakanyanya kupfutirwa kunobudirira.

(4) Chimiro uye chinzvimbo chekushivirira chokwadi chezvisere zvakagadzika migero mirefu uye maburi pamutumbi weimpeller weImpeller Head akanyanya kuomarara.

a.Kambani yedu inotora iyo inotengwa kunze kwenyika yakakosha machining centre, iyo inogona kupedzisa hurongwa hwese kubva pa indexing kusvika pakugaya kusvika pakugaya zvakanaka;uye kubva pakunongedza kusvika pakuboora kuenda ku chambering kuenda ku reaming uye mamwe maitiro pane impeller panguva imwe chete nekusunga.

b.Ichavimbisa kuenzana kwekushanda kweImpeller Head, uye nguva yekuenzanisa iri pakati pe12-15n · mm (yerudzi rwenyika 1 8.6n · mm), iyo inoderedza zvikuru ruzha rwemichina.

(5) Iyo blade, vhiri rekugovera uye ruoko rwekutungamirira rweImpeller Head zvinogadzirwa nezvinhu zvisingapfeki; uye nekugadzirwa kweShinto.Japan, iyo inoita mutsauko wehuremu weblade inodzorwa mukati me2g.Kunyanya kuderedza ruzha panguva yekushanda kweImpeller Head uye inowedzera hupenyu hwebasa rezvikamu zvinodyiwa.

6

(7) Yakanaka kutaridzika, yakapfava chimiro, yakanakira kugadzira uye kugadzirisa, yakaderera ruzha.

(8) Isa chigadziro chemuganho paImpeller Head: kana iyo Yepamusoro yekudzivirira ndiro yakavhurwa kuti igadziriswe, iva nechokwadi chekuti michina haigone kutangwa, nekudaro ichidzivirira kuchengetedzwa kwevashandi vekuchengetedza.

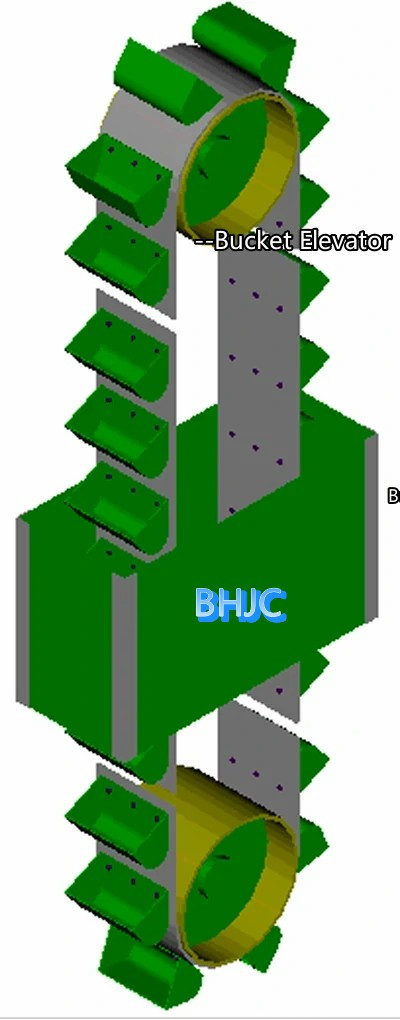

C.Bucket Elevator:

Iyo bucket elevator inoumbwa ne cycloidal pin vhiri reducer;Okumusoro neazasi rollers;conveyor belt;hopper;mbiya yakavharwa uye tension device.

Iyo yepasi yekudyira port yebucket lift yakabatana ne screw conveyor, uye yekumusoro yekuburitsa chiteshi yakabatana neinoparadzanisa.

Chivharo cheBucket Elevator chinotora chimiro chewelding, chine chitarisiko chakanaka uye kusimba kwakanaka.

Iyo yepamusoro uye yepasi roller inotora iyo yepamusoro squirrel cage chimiro nedhayamita imwechete, iyo inovandudza kupokana pakati pebhandi rekusimudza uye pulley, kudzivirira skid phenomenon, uye kuderedza pre-kusimbisa simba rekusimudzira bhandi.

Chivharo chebhakiti rinosimudza rine musuwo wekupinda, unogona kugadzirisa uye kutsiva hopper.Nekuvhura chivharo chemusuwo pamusuwo wepasi wekupinda, iyo yakaderera drive inogona kuchengetedzwa uye simbi yekupfura block pazasi inogona kubviswa.

Muchina uyu unoshandisa bhandi rakatsetseka kutenderera.Panguva yekushanda, hovha yakamisikidzwa pabhandi rekutakura inokwenya simbi yakapfurwa pazasi pe lifti;pasi pekutyaira kwemota yekusimudza, pfuti yesimbi inoburitswa ne centrifugal gravity uye kupihwa muSeparator.

Elevator yakashongedzerwa neseti yetension mudziyo.Kana bhanhire rakasununguka, bhanhire rinofanira kusimbiswa nekugadzirisa mabhoti ekugadzirisa kumativi ose echikamu chepamusoro cheelevator.Kugadzirisa chiyero ndeye 100 mm.

Pane vhiri rekupuruzira mugomba rezasi remugomo rinosimudza, iro rinogona kuona uye kuronda mamiriro ekushanda emugomo.Kamwe bhaketi rinosimudza risingatenderere kana kutsvedza, rinogona kudzosera chiratidzo kuPLC nenguva, kuve nechokwadi chekushanda kwakachengeteka kwemidziyo.

D.Screw Conveyor:

Iyo screw conveyor inoumbwa ne cycloidal pini vhiri reducer, screw shaft, conveyor cover, inotakura nechigaro, nezvimwe.

Iyo spiral blade inogadzirwa ne16Mn zvinhu, uye madenderedzwa ayo emukati nekunze anodhonzwa mushure mekugadziriswa nehunyanzvi tekinoroji.

Iyo yose screw shaft inogadziriswa yakazara mushure mekugadzira, nekudaro ichiva nechokwadi che coaxiality yemativi ese ari maviri e screw shaft.

Iyo Screw Conveyor inoendesa pfuti yesimbi yakaunganidzwa nechepasi hopper kune inosimudza bucket.

Iyo pitch uye yekunze denderedzwa saizi ndeyechokwadi, izvo zvinovandudza hupenyu hweiyo spiral uye inoderedza ruzha rwekumhanya.

Ichi chikamu chikamu chakakosha chesimbi yekupfura circulation system yemidziyo.

Kune chikamu ichi, Kambani yedu yakaziva seriation, iine chimiro chepamusoro-siyana, shanduko, yakagadzikana uye yakavimbika kuita.

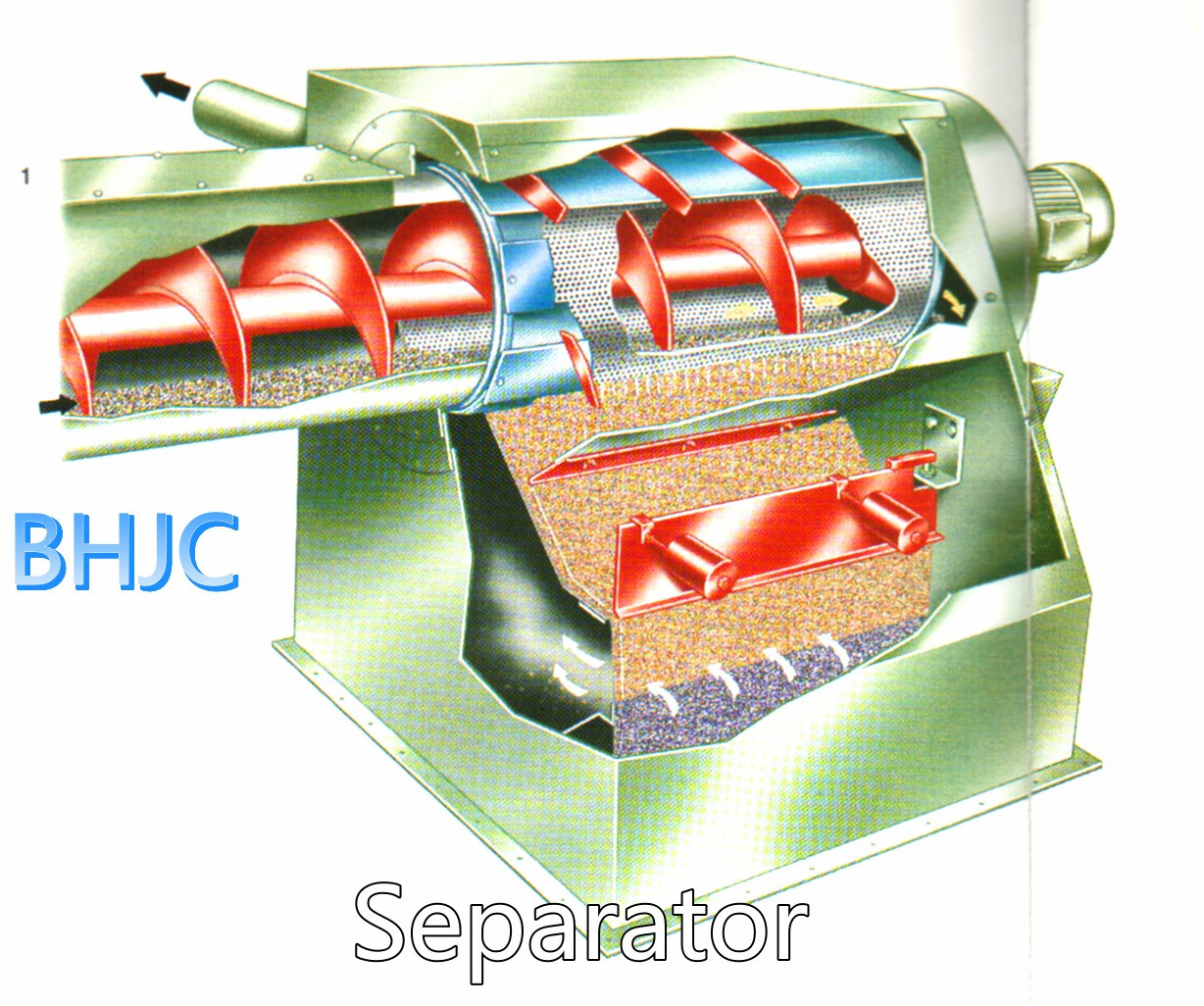

E.Separator:

Kutora yepamusoro "BE" mhando yakazara-curtain separator.

Iyi kupatsanura yakazvimiririra yakagadziridzwa nekambani yedu pahwaro hwekunyura zvizere tekinoroji yeSwitzerland GEORGE FISCHER DISA (GIFA) neAmerican Pangborn kambani, uye mushure mekuramba yakagadziridzwa.Ndiyo yazvino mhando yekuparadzanisa kambani yedu

Iyo yekuparadzanisa inoumbwa nezvikamu zviviri: dhiramu skrini uye mhepo yekuparadzanisa system.

Chidzitiro chedhiramu chinoumbwa nemukati mespiral blades, ekunze spiral blades, chidzitiro chemuviri, tsigiro shaft uye chikamu chekutumira, gonhi rekuchengetedza uye chivharo;

Mhepo yekuparadzanisa system inoumbwa negiravhiti yejecha rekuvhara ndiro, deflector, yekutanga-level skimming plate, yechipiri-level skimming plate, suction port, cover, screen, anti-wear plate, shot storage bucket uye air volume regulating valve.

Separator kugadzirisa:

① Iyo yakanakisa yekuparadzanisa mhedzisiro yeSeparator inowanikwa nekugadzirisa huremu chinzvimbo pagedhi, nzvimbo yekugadziridza ndiro pane yekutanga neyechipiri skimming mahwendefa, uye butterfly valve papombi.

② Kuburikidza nenzira idzi, kupatsanurwa kuchaita pamusoro pe99.5%, uye kuchaderedza zvakanyanya kupfekwa kwemashizha emuchina wekupfurwa.

Iyo yakanakisa dhayamita yesimbi yakapfurwa yerudzi urwu rweSeparator i0.7 ~ 2.5, uye kugona kwayo kwekuparadzanisa ≥99.5%.

F.Steel shot distribution system:

Ivhavha yegedhi rekupfura inodzorwa necylinder inoshandiswa kudzora kupihwa kwesimbi inopfurwa kure.

Isu tinokwanisa kuburikidza nekugadzirisa mabhaudhi pane pfuti controller kuti tiwane inodiwa pfuti kuputika huwandu.

Iyi tekinoroji inogadzirwa yakazvimirira nekambani yedu.

Kusarudzwa kwepfuti: Inokurudzirwa kushandisa simbi yakakandwa, kuomarara LTCC40 ~ 45.

G.Control system:

Air control system:

Iyo air control system inoumbwa nemhepo sosi yekugadzirisa zvikamu, mavharuvhu emhepo uye pneumatic actuators.Kuti uve nechokwadi chekushanda kwakavimbika kwemidziyo, mavharuvhu emhepo ese ari epamba ane mukurumbira chigadzirwa chemhando.

Electronic control system

① Iyi sisitimu inoona kutonga kwese kwemushini wekupfutidza.

② Iyi sisitimu inotora programmable logic controller (PLC) semusimboti uye inoshandisa emhando yepamusoro zvinhu zvemagetsi.Iyo ine akawanda mabhenefiti akadai seakavimbika kushanda, yakakwirira dhigirii ye otomatiki, uye yakakwana kuchengetedza mabasa.

③ Iyo huru magetsi ehurongwa uhu inotora 3 * 380v AC magetsi, iyo yekudzora loop inotora imwe-chikamu 220v AC magetsi, uye control transformer inoderedza iyo 380v voltage kusvika 220v uye inoipa kune yekudzora loop.

④ Iyi sisitimu ine yakaringana kukanganisa alarm basa rekubatsira vashandisi kana vashandi vekugadzirisa nekukurumidza kuwana pari kukanganisa, kuderedza nguva, uye kugadzirisa kushanda zvakanaka.

⑤ Zvikamu zvemagetsi zvegadziriro iyi zvakaiswa pakati pemagetsi emagetsi kuti zvive nyore kushanda nekugadzirisa.

H.Mesh bhandi conveyor system:

Iyo mesh bhandi conveyor system ine yekudyisa mesh bhandi, rotary mumhanyi, tensioning mudziyo, nezvimwe.

Iyo mesh bhandi inofambiswa nedhiraivha mudziyo inodzorwa neiyo frequency converter kuti ive nechokwadi chekumhanya kweiyo basa-chidimbu kuti uwane nhanho-shoma yekumhanyisa mutemo, kuitira kuti basa-rinogona kucheneswa panguva imwe.

5.After sale service:

The chigadzirwa waranti nguva igore rimwe.

Munguva yewaranti nguva, zvikanganiso zvose uye zvikamu zvakakanganisika zvekutonga kwemagetsi uye mashizha emagetsi nekuda kwekushandiswa kwemazuva ose zvichagadziriswa uye zvinotsiviwa (kunze kwekupfeka zvikamu).

Munguva yewaranti, iyo mushure mekutengesa sevhisi inoshandisa "pakarepo" mhinduro.

Hofisi yekambani yedu mushure mekutengesa sevhisi ichapihwa tekinoroji sevhisi munguva mukati memaawa makumi mana nemasere mushure mekugamuchira chiziviso chemushandisi.

6.RAQ

Kuti tipe mhinduro dzakanakisa dzezvigadzirwa zvako, ndapota tizivise mhinduro dzemibvunzo inotevera:

1. Ndezvipi zvigadzirwa zvaunoda kurapwa?Dai watiratidza zvinhu zvako.

2.Kana kune marudzi akawanda ezvigadzirwa zvinoda kurapwa, Ndeipi hukuru hukuru hwekushanda-chidimbu?Kureba * upamhi * urefu?

3.Chii uremu chikuru basa-chidimbu?

4.Ndeipi kugadzirwa kwekubudirira kwaunoda?

5.Zvimwe zvimwe zvakakosha zvemichina?