BHQ26 yakatevedzana jecha blasting mudziyo ine mutengo wehupfumi

jecha rinoputika mudziyo

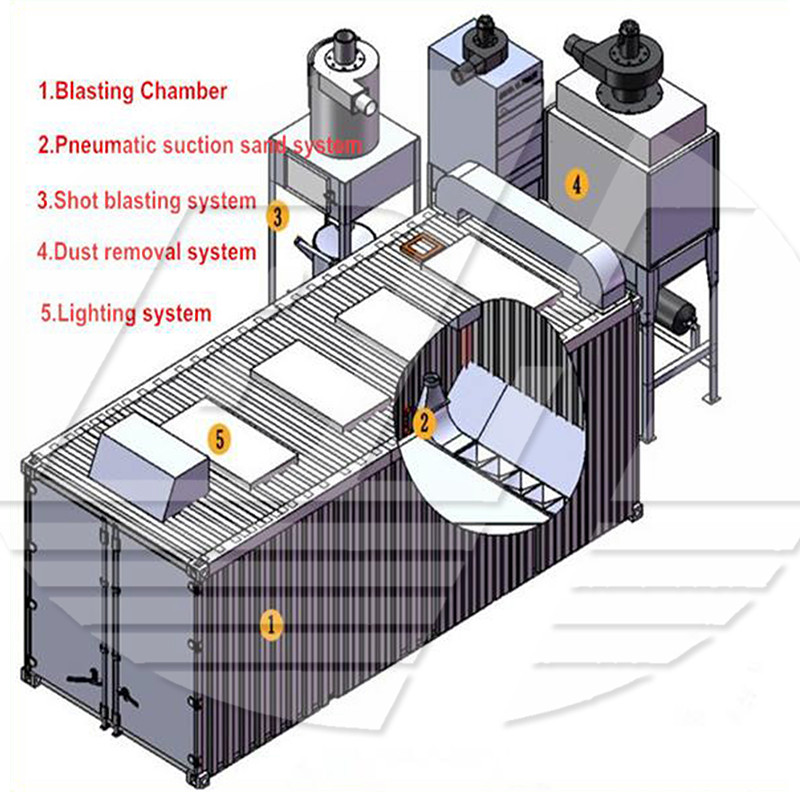

Iyo inonyanya kuumbwa nepfuti blaster assembly, pfuti inoputika kamuri, trolley yekufambisa sisitimu, guruva rekubvisa system, magetsi ekudzora system uye zvimwe zvikamu.

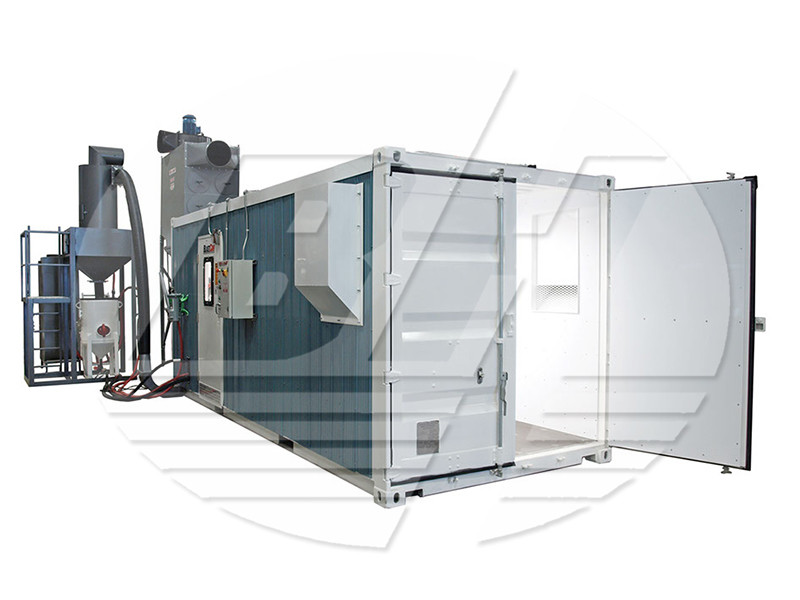

1 Imba yekuputira pfuti

Iyo goko repfuti inoputika yekuchenesa imba inogadzirwa neruvara rwesimbi rock wool sandwich composite board uye rectangular simbi welding riveting chimiro, inova yakasimba, yakavharwa uye yakakura nzvimbo yekushanda yekupfura kuputika kweiyo workpiece.Imba yekuchenesa inoputika inoumbwa nemadziro ekuruboshwe nekurudyi, madziro ekumashure, ndiro yepamusoro, rabha rinorinda ndiro, uye gedhi.Imba yekuputira kamuri ine marambi esimbi halide (yakadzivirirwa nesimbi isina tsvina mesh).Imo mukati mekamuri inodzivirirwa nechena kupfeka-resistant rubber guards, uye varindi vose vanoiswa nebead bolts.Gonhi rekamuri yekuputira pfuti rinotora mudziyo wemhando yemanyorero folio.

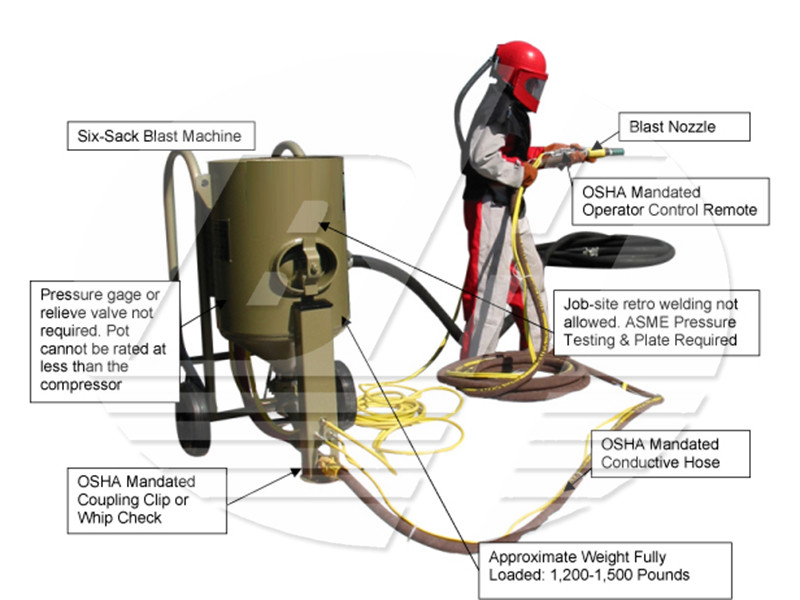

2 Shot blaster musangano

The shot blaster assembly inoumbwa netangi, mhuno, muromo, pneumatic element, etc. Iyo yakakura-inogoneka inoenderera kuvhiya kaviri-pfuti blaster.Iyo muromo inogadzirwa ne boron carbide uye inogara kwenguva refu.Iyo muromo inogadzirwa ne-ultra-wearable high-pressure rubber tube Pakati pavo, kugadzirwa kwematangi kune hunhu hwekugadzira midziyo yekumanikidza.

3 Piritsi zvinhu kutenderera yekuchenesa system

Iyo pellet inotenderera yekuchenesa mudziyo inosanganisira yekutenderera system uye pellet yekuparadzanisa yekuchenesa system, iyo inoumbwa ne screw conveyor, bucket lift, pellet jecha separator, pellet yekugovera gedhi vharafu, uye pellet yekuendesa pombi.

Screw conveyor:

Iyo screw conveyor inoumbwa necasing, screw shaft, bearing ine chigaro, drive mechanism, etc. Icho chikamu cheserialized chekambani yedu, ine hupamhi hwepamusoro, kuchinjika kwepamusoro, uye yakagadzikana uye yakavimbika kuita.

Ichi chikamu chine basa rekufambisa musanganiswa wejecha rekupfura kune elevator.Iyo screw conveyor iri pazasi pepfuti blasting yekuchenesa kamuri, uye screw blades dzakasungirirwa kune drive shaft.Kana ichishanda, mota inotakura inotyaira screw conveyor kuti itenderere kuburikidza ne cycloid inoderedza kutakura mapellets kuenda kuchiteshi chekuburitsa, uye ipapo chiteshi chekuburitsa chinotamisa mapellets akapararira uye musanganiswa weguruva kuzasi kwerifiti.

Migumo miviri yescrew conveyor inodzivirirwa nechisimbiso chetatu-nhanho, chivharo chelabyrinth chisimbiso chinowedzerwa mukati meplate yekupedzisira, chisimbiso chemafuta chinoshandiswa kudzivirira pakati, uye kutakura kunoparadzaniswa kubva kune ndiro yekupedzisira kunze kwekuguma. ndiro.Kamwe mapellets uye guruva zvakawedzerwa, ivo vanodonha kubva pakakoromo pakati pekupedzisira ndiro uye kubereka uye havazopindi mukutakura.

Bucket lift:

Iyo bucket elevator inoumbwa ne cycloidal pini vhiri kumhanya inoderedza, ekumusoro uye yakaderera rollers, conveyor bhandi, hopper, yakavharwa mbiya uye tensioning mudziyo, nezvimwewo, uye centrifugal giravhiti inoshandiswa kuvharika.

Paunenge uchishanda, hovha yakagadzika pabhandi rekutakura inokwenya mapellets pazasi uye inotumira mapeti kumusoro, yobva yadonha ne centrifugal gravity.Kutora rakakosha bhandi rekutapurirana repolyester waya musimboti, kusimba kwepamusoro uye kuita kwakanyanya kusimba.

Iyo pulley inotora squirrel-cage structure ine zvishoma zvishoma mukati, uye imwe neimwe inotaura inogadziriswa nechamfering.Haisi kungovandudza kukakavara pakati pe tepi yekusimudza uye pulley, inodzivisa kutsvedza kwechinyakare chechiedza chekare uye pulley kune bhanhire, asi zvakare inoderedza kufungidzira kwebhanhire rinosimudza uye rinowedzera hupenyu hwebasa;panguva imwecheteyo, inodzivisa kuiswa kwebhomba rakapararira Pakati pepulley uye bhanhire rinokanganisa kutapurirana.

Pane 10% margin yekusimudza.Nekuti iyo hoist inodonha ne centrifugal gravity, pese painodonha, pachagara paine chikamu chechinhu chinowira kumashure, saka zvinodikanwa kuwedzera huwandu hwekusimudza zvakakodzera.

Pellet separator:

Muchina uyu unotora wepasirese wepamberi yakazara-curtain kuyerera keteni mhepo yekuparadzanisa piritsi residue separator, uye kugona kwayo kwekuparadzanisa i ≥99.5%.Iyi kupatsanura ndiyo yazvino mhando yekuparadzanisa kambani yedu.Iyo yekuparadzanisa chimwe chezvikamu zvakakosha zvechigadzirwa ichi.Saizi yekugadzira yenzvimbo yekuparadzanisa inobata zvakananga mhedzisiro yekuparadzanisa.Kana iyo yekuparadzanisa mhedzisiro isiri yakanaka, inomhanyisa kupfeka kweblade inoputika.

4 Trolley conveyor system

Flat motokari yekufambisa inogamuchirwa;kutakura mutoro kunogadziriswa maererano nemamiriro chaiwo emutengi.Zvinoenderana nemamiriro eiyo workpiece, sunda nemaoko mota yakafuratira mukamuri yekuchenesa kuti ugamuchire pfuti kudongorera.Kumberi kwevhiri kunogona kuve ne polyurethane scraper yekukwenya kubva kune projectiles pamusoro penjanji.

5 Huru yekubvisa hurongwa

Dust yekubvisa sisitimu inosanganisira sefa cartridge guruva muunganidzi, fan, mota, pombi, chimney, nezvimwe.

Automatic pulse back-flushing, guruva-kubvisa valve inotora pneumatic control, uye guruva rinounganidza mbiya rine roller rinorongwa pasi peash hopper, kudzivirira yechipiri guruva chiitiko chinokonzerwa nekudzokera shure.

Iyo guruva sefa cartridge inogona kubviswa nyore nyore kuchenesa uye kushandiswa zvakare.

6 Electrical system

Shot blaster, gonhi rekugadzirisa, projectile controller uye projectile circulation system zvese zvakashongedzerwa nemagetsi interlock uye yekuzvivharira nzira yekuve nechokwadi chekushanda kwakavimbika kwemidziyo uye kuchengetedzeka kwevashandisi.Iyo huruva inofuridza kumashure inofefetera inotora otomatiki pulse control.